Send your print, drawing or sketch to office@UltraFastenersUSA.com or use our Quick Quote link with your request or question

Lock Nuts All Makes, Models & Part Numbers

Not all styles listed…Please call for immediate support 1.888.508.9810

Inch & Metric, Various Materials

Request Made in USA

Mechanical nuts are essential components used in conjunction with bolts and screws to create secure connections in various applications. Here are some of the most common types of mechanical nuts made in the USA:

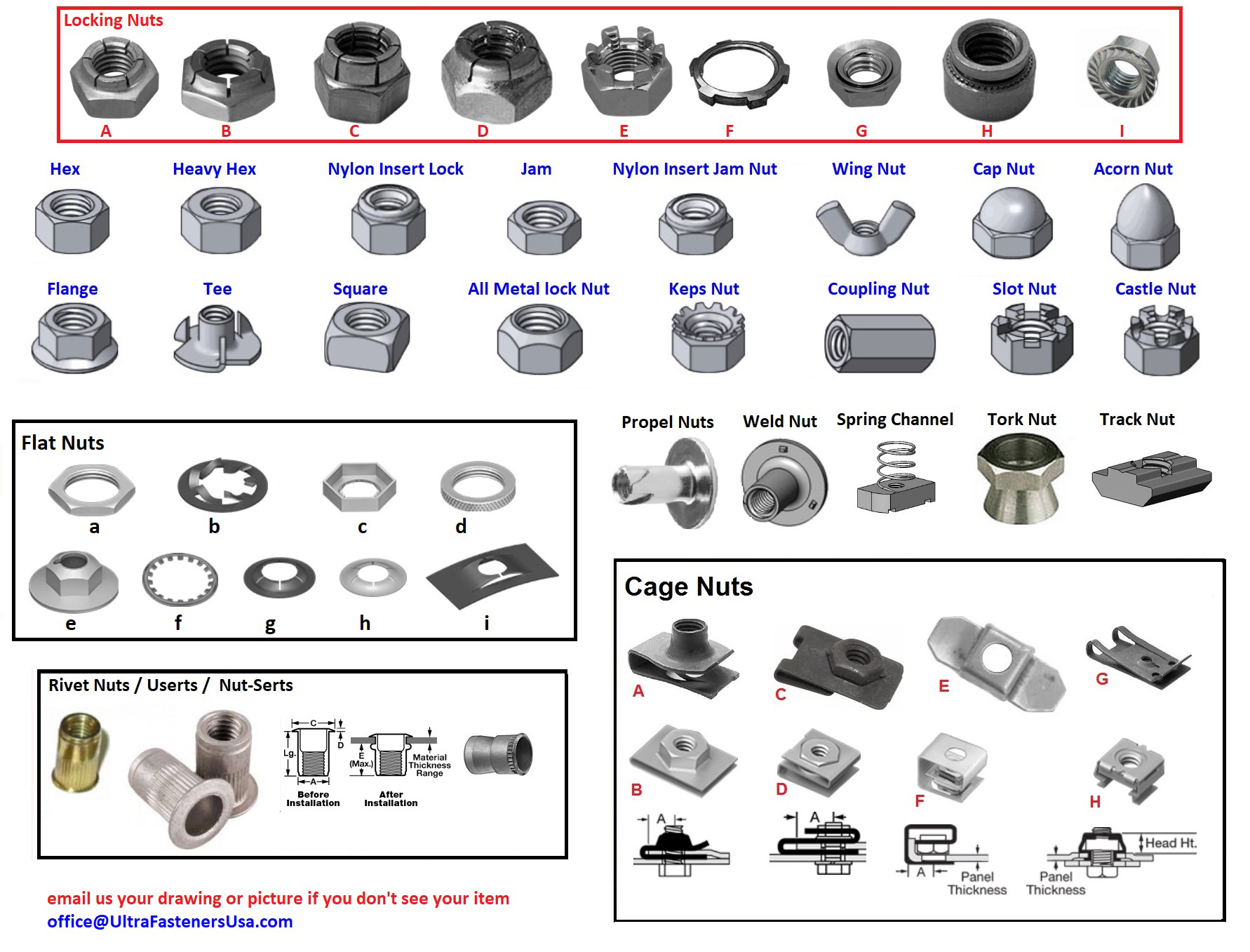

- **Hex Nuts**: The most common type of nut, characterized by a hexagonal shape. They are used with bolts and provide a simple and effective means of fastening.

- **Lock Nuts**: Designed to prevent loosening due to vibration or movement. They can be either nylon-insert lock nuts (which have a nylon ring that grips the bolt) or all-metal lock nuts (which create friction against the bolt threads).

- **Wing Nuts**: Featuring large “wings” for hand-tightening, these nuts are often used in applications where frequent adjustments are needed, such as in furniture assembly.

- **Flange Nuts**: These nuts have a wide flange at one end, which helps distribute the load over a larger area and can eliminate the need for a washer.

- **Cap Nuts (Acorn Nuts)**: These nuts have a rounded end that covers the exposed end of a bolt, providing a finished appearance and protecting the threads from damage.

- **T-Nuts**: Used primarily in woodworking, T-nuts have a flange that creates a secure attachment point within a material, allowing for easy bolt insertion.

- **Square Nuts**: These nuts have a square shape, which can provide a better grip in certain applications and are often used in conjunction with square bolts.

- **Jam Nuts**: These are thin nuts used in conjunction with a standard hex nut to lock it in place, preventing loosening.

- **Nylon Lock Nuts**: Similar to lock nuts, these have a nylon insert that grips the bolt threads, providing resistance to loosening from vibrations.

- **Serrated Flange Nuts**: These have serrations on the flange that grip the material, providing additional resistance to loosening.

Each type of mechanical nut is designed for specific applications and load conditions, ensuring reliable connections in various industries, including construction, automotive, machinery, and aerospace.