Socket head products, particularly socket head cap screws and bolts, are commonly used fasteners in various applications. Here’s an overview of their styles, types, and applications:

Styles

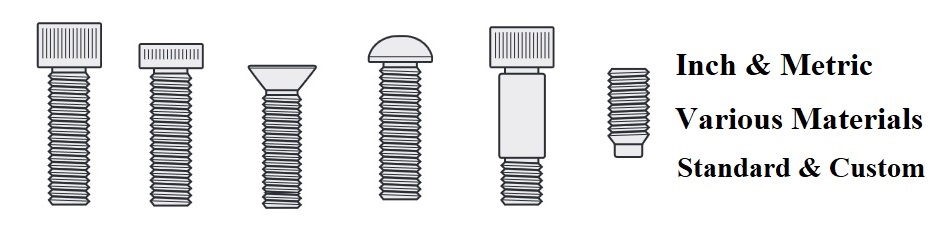

- **Socket Head Cap Screw**: This is a cylindrical screw with a hexagonal socket in the head. It allows for a clean and flush finish when installed and is often used in tight spaces.

- **Flat Socket Head Screw**: Features a flat top and lower height, often used in applications where a flush finish is necessary.

- **Extended Socket Head**: These screws have a longer shaft than standard socket screws, providing additional reach for fastening in deep or hard-to-reach areas.

Types

1. **Material Types**:

– **Steel**: Commonly used for general applications, available in various grades (e.g., Grade 8).

– **Stainless Steel**: Offers corrosion resistance, suitable for outdoor or marine applications.

– **Aluminum**: Lightweight and resistant to corrosion, used in aerospace and automotive industries.

– **Plastic**: Non-conductive and resistant to chemicals, used in electronic and medical equipment.

2. **Drive Types**:

– **Hex Socket**: Requires a hex wrench for installation.

– **Torx Socket**: Features a star-shaped socket for better grip, reducing the risk of stripping.

– **Square Drive**: Provides a more secure fit and torque application.

Applications

– **Machinery and Equipment**: Used in assembling machinery where tight tolerances and secure fastening are required.

– **Automotive Industry**: Commonly found in vehicle assembly, especially in components that require a flush finish.

– **Aerospace**: Used in critical applications where weight savings and corrosion resistance are crucial.

– **Electronics**: Often used in assembling electronic enclosures or devices where a non-conductive option is necessary.

– **Construction**: Used in structural applications, particularly where aesthetics is important, and a clean finish is desired.

Overall, socket head products are favored for their versatility, strength, and ease of use in a variety of industrial and consumer applications.

SOCKET HEAD CAP SCREWS DETAILS INCLUIDE TENSILE STRENGTH, YIELD STRENGTH, HARDNESS HRC

INFORMATION PROVIDED IS FOR GENERAL REFERENCE ONLY

BUTTONS & FLAT SPEC: ANSI B18.3-1986 AND ASTM F835 | SOCKETS & SHOULDERS SPEC: ANSI B18.3-1986 AND ASTM A574-92A | DOWEL PINS: ASME B18.8.2 | PIPE PLUGS: ANSI B1.20.3-1976

Product li ne includes, but not limited to made in USA, domestic & American made,

Socket Screws, Socket Head Cap Screws, Flat Socket Cap Screws, Button Socket Cap Screws,

Socket Shoulder Screws, Low Head Socket Cap Screws, Dowel Pins, Set Screws (Multiple Point Types)

If you don’t see what you require… call or email for immediate support